- Home

-

PRODUCT

- CCTV CAMERAS

- BIOMETRIC ATTENDANCE SYSTEM

- FIBER PRODUCTS

- WIRELESS CAMERA

- NETWORKING

- ANNUAL MAINTENANCE CONTRACT

- ANTI-THEFT SOLUTION

- 4G ROUTER

- THERMAL MONITORING PRODUCTS

- RESIDENTIAL

- DOOR LOCK SYSTEM

- INTRUSION ALARM

- HOTEL LOCK SOLUTIONS

- SMART HOME

- IP MULTI-DOOR PHONE APARTMENT SOLUTION

- ENTRANCE PRODUCTS

- VIDEO DOOR PHONE

- STORAGE

- CARDS

- SOLUTIONS

- FIRE PROTECTION SYSTEM

- About us

- CONTACT US

- CAREER

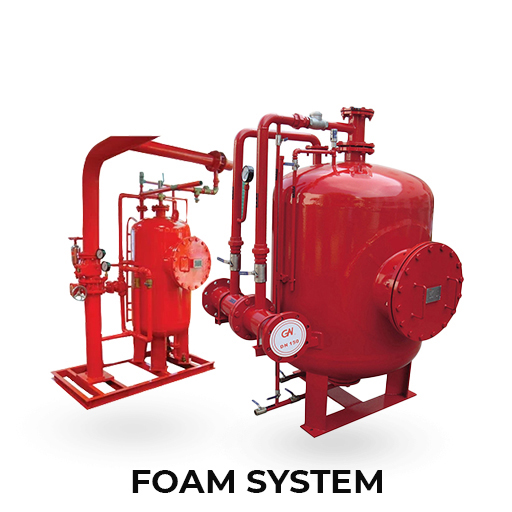

Foam System

Foam serves as a crucial blanketing agent in fire suppression systems, employing the principle of oxygen exclusion along with preventing the release of hydrocarbon fuel vapors from the fire. Additionally, the water content in foam contributes to cooling the fire, making it an effective solution for combating fires involving flammable liquids.

In modern foam systems, foam concentrate is blended with water at ratios typically ranging from 3% to 6%. This mixture is then passed through an aerating device, resulting in the formation of foam with varying expansion ratios:

– Low expansion: 7.5% to 20

– Medium expansion: 20 to 250

– High expansion: 250 to 1000

The quantity of foam required varies depending on the nature of the fire risk and the type of tanks involved. Application times are also specified in relevant codes to ensure effective fire suppression measures.

Maintaining an adequate stock of foam compound is essential for ensuring readiness to tackle fire emergencies. According to regulations, the stock of foam compound must be sufficient to meet the requirements of tanks needing maximum foam quantities, with a reserve equivalent to at least double the demand.

By incorporating foam systems into your fire safety infrastructure, you can significantly enhance your facility’s ability to respond to fire incidents involving flammable liquids. Contact us today to learn more about our foam system solutions and ensure comprehensive fire protection for your premises.

Foam System for Oil Tank:

Foam serves as a crucial blanketing agent in fire suppression systems, employing the principle of oxygen exclusion along with preventing the release of hydrocarbon fuel vapors from the fire. Additionally, the water content in foam contributes to cooling the fire, making it an effective solution for combating fires involving flammable liquids.

Foam systems for oil tanks typically consist of foam concentrate storage tanks, proportioning devices, foam solution delivery pipes, foam generators, and control systems. When a fire is detected, the foam concentrate is mixed with water and delivered to the fire through foam solution delivery pipes and foam generators. The foam blanket then forms over the surface of the flammable liquid, rapidly extinguishing the fire.

There are different types of foam systems used for oil tanks, including high-expansion foam systems and low-expansion foam systems. High-expansion foam systems produce large volumes of foam with a low density, making them suitable for filling enclosed spaces, such as storage tanks and bunded areas. Low-expansion foam systems produce denser foam with smaller bubbles, making them ideal for covering larger surface areas, such as open spills or fires involving large tanks.